Introduction

Three phase induction motor is extensively used for various kinds of industrial drives. The three phase induction motor has a three phase wound stator to which the three phase supply is connected. The power transfer to the rotor is by ’induction’ and that is why these motors are called induction motors. Three phase induction motors possess many advantages such as simple design, low cost, rugged construction and reliable operation. They have good speed regulation and high starting torque.

Construction

The main parts of a three phase induction motor are (i) Stator and (ii) Rotor. The stator is the stationary part and the rotor is the rotating part. The rotor is separated from the stator by a small air gap whose thickness(length) depends on the power rating of the motor. There are two types of three phase induction motors based on the construction of rotor

1. Squirrel cage induction motor

2. Slip ring induction motor

Applications of three phase induction motors

Squirrel cage induction motors are used in centrifugal pumps, fans, conveyors, compressors, reciprocating pumps, line shafting, lathe works, line shafting, etc.

Slip ring induction motors are used in lifts, hoists, cranes, conveyors, pumps, flour mills, etc.

Advantages of induction motors

1. Simple design.

2. Low cost compared to other motors of the same capacity.

3. High overload capacity.

4. Very rugged construction.

5. Requires little maintenance.

6. Have reasonably good efficiency and provides reliable operation.

7. Has good speed regulation and high starting torque.

8. Uses readily available power supply (three phase AC).

Disadvantages of induction motors

1. Wide variation in speed is not possible.

2. Its speed decreases with increase in load.

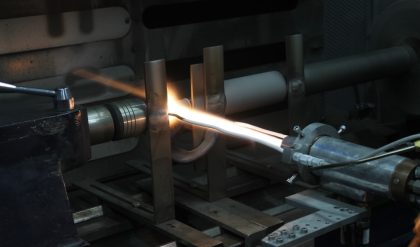

Figure 10.1: Typical power transmission system

Comments are closed.