when a horizontal force is applied to a static body to move the same, a frictional force equal to the applied force develops in the opposite direction resisting the motion. As long as the body does not move , this force is called static frictional force. Now if the applied force is increased, the frictional force in the opposite direction increases proportionately until it reaches the limit after which if the applied force is increased, the body starts moving. This threshold force is called static or limiting force of friction.

Laws Of Limiting Friction

· The direction of force of friction is always opposite to the direction of motion.

· Force of friction depends upon the nature and state of polish of the surfaces in contact.

· It acts tangentially to the interface between the two surfaces.

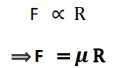

· Magnitude of limiting friction “F” is directly proportional to the normal reaction “R” between the two surfaces in contact.

휇 = The proportionality constant called the COEFFICIENT OF FRICTION

· Magnitude of limiting friction between two surfaces is independent of area and shape of surfaces in contact so long as the normal reaction remains the same.

Methods to reduce Friction:

Introduction:-

Friction is a necessary evil. In some situations, it plays a positive role whereas in others, it is not needed. The net efficiency of any machine depends on the amount of friction present in that machine, because a large part of the input energy of all machines is wasted in overcoming friction between its various parts, and thus the total output from the machine decreases. There is thus a need to find ways to decrease friction in order to make machines more efficient and to increase their life time. These ways of decreasing friction can be applied in different parts of machines according to the function of that part, and thus a more efficient machine is constructed. The following techniques are different ways to decrease friction used widely:

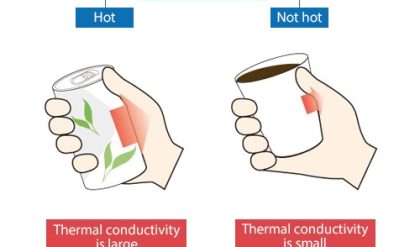

· USE OF LUBRICANTS The use of lubricants like oil and grease helps to reduce friction by forming a thin film between different parts of a machine. This film covers up the scratches and lumps present on the surfaces of different parts and thus makes the surface more even than before. This reduces interlocking between the two surfaces, and hence the parts of the machine run smoothly.

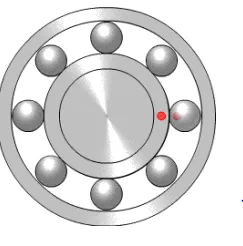

· USE OF BALL BEARINGS Two moving surfaces in a machine are fixed by placing small balls or rollers made out of steel in between them. This way, the moving parts avoid direct contact and sliding friction is changed to rolling friction. Rolling friction is less than sliding friction, thereby decreasing the amount of friction in the machine.

· BY POLISHING The unevenness of surfaces can be reduced by polishing them. This will reduce the interlocking between surfaces in contact thus reducing friction.

· USING SOFT, FINE POWDER Soft, fine powder like talcum powder and graphite powder also helps in filling in the microscopic scratches and grooves on a surface and thus make it more even and less prone to interlocking with other surfaces. Thus, friction is reduced.

· STREAMLINING Streamlining is the process of making a machine’s shape such, that avoids resistance from air and water molecules while moving. For example airplanes have a streamlined shape which reduces friction between air molecules while flying. This is because fluids move with less friction over a streamlined surface, and the object moves forward as if cutting through them. The following diagram shows a streamlined and a blunt body:-

· Use of correct combination of surfaces in contact:- Use of alloys on moving and sliding parts reduces friction because alloys have a low coefficient of friction.

Comments are closed.