Introduction

Carpentry may be defined as the process of making wooden components. It starts from a marketable form of wood and ends with finished products. It deals with the building work, furniture, cabinet making. Etc. joinery, i.e., preparation of joints is one of the important operations in all woodworks. It deals with the specific work of carpenter like making different types of joints to form a finished product.

Timber:

Timber is the name given to the wood obtained from well grown trees. The trees are cut, sawn into various sizes to suit building purposes. The word, ‘grain’, as applied to wood, refers to the appearance or pattern of the wood on the cut surfaces. The grain of the wood is a fibrous structure and to make it strong, the timber must be so cut, that the grains run parallel to the length.

Timber Sizes

Timber sold in the market is in various sizes and shapes. The following are the common shapes and sizes.

a. Log ‐ The trunk of the tree which is free from branches.

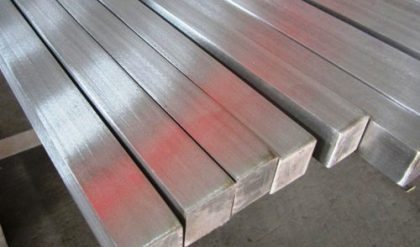

b. Balk ‐ The log, sawn to have roughly square cross section.

c. Post ‐ A timber piece, round or square in cross section, having its diameter or side from

175 to 300mm.

d. Plank ‐ A sawn timber piece, with more than 275 mm in width, 50 to 150 mm in

thickness and 2.5 to 6.5 meters in length.

e. Board ‐ A sawn timber piece, below 175 mm in width and 30 to 50 mm in thickness.

f. Reapers‐ Sawn timber pieces of assorted and non‐standard sizes, which do not confirm to the

above shapes and sizes.

Classification of Timber

Wood suitable for construction and other engineering purposes is called timber. Woods in general are divided into two broad categories: Soft woods and Hard woods. Soft woods are obtained from conifers, kair, deodar, chir, walnut and seemal. Woods obtained from teak, sal, oak, shisham, beach, ash mango, neem and babul are known as hard wood, but it is highly durable. Another classification of woods is based on the name of the trees like teak, babul, shisham, neem, kair, chir, etc.

Seasoning of Wood

A newly felled tree contains considerable moisture content. If this is not removed, the timber is likely to wrap, shrink, crack or decay. Seasoning is the art of extracting the moisture content under controlled conditions, at a uniform rate, from all the parts of the timber. Only seasoned wood should be used for all carpentry works. Seasoning makes the wood resilient and lighter. Further, it ensures that the wood will not distort after it is made into an object.

Characteristics of Good Timber

The good timber must possess the following characteristics

a. It should have minimum moisture content, i.e., the timber should be well seasoned.

b. The grains of wood should be straight and long.

c. It must retain its straightness after seasoning.

d. It should produce near metallic sound on hammering.

e. It should be free from knots or cracks.

f. It should be of uniform color, throughout the part of the wood.

g. It should respond well to the finishing and polishing operations.

h. During driving the nails and screw, it should not split easily.

Comments are closed.