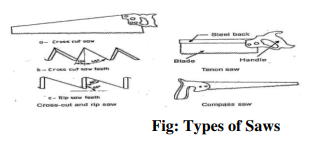

Saws

A saw is used to cut wood into pieces. There are different types of saws, designed to suit

different purposes. A saw is specified by the length of its toothed edge.

Types of Saws

Cross‐Cut Saw or Hand Saw

It is used to cut across the grains of the stock. The teeth are so set that the saw kerf will be wider

than the blade thickness. This allows the blade to move freely in the cut, without sticking

Rip Saw

It is used for cutting the stock along the grains. The cutting edge of this saw makes a steeper

angle, i.e., about 60° whereas that of crosscut saw makes an angle of 45° with the surface of the stock.

Tenon Saw

It is used for cutting the stock either along or across the grains. It is used for cutting tenons and

in fine cabinet work. However, it is used for small and thin cuts. The blade of this saw is very

thin and so it is stiffened with a thick back steel strip. Hence, this is sometimes called as

back‐saw. In this, the teeth are shaped like those of cross‐cut saw.

Compass Saw

It has a narrow, longer and stronger tapering blade, which is used for heavy works . It is mostly

used in radius cutting. The blade of this saw is fitted with an open type wooden handle.

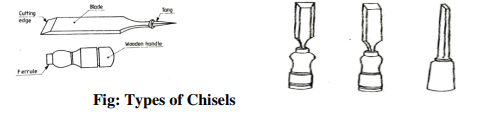

Chisels

Chisels are used for cutting and shaping wood accurately. Wood chisels are made in various

blade widths, ranging from 3 to 50 mm. They are also made in different blade lengths. Most of

the wood chisels are made into tang type, having a steel shank which fits inside the handle.

These are made of forged steel or tool steel blades.

Types of Chisels

Firmer Chisel

The word ‘firmer’ means ‘stronger’ and hence firmer chisel is stronger than other chisels.

It is a general purpose chisel and is used either by hand pressure or by a mallet. The blade of a

firmer chisel is flat, as shown in figure.

Dovetail Chisel

It has a blade with a beveled back, as shown in Figure, due to which it can enter sharp comers

for finishing, as in dovetail joints.

Mortise Chisel

It is used for cutting mortises and chipping inside holes, etc. The cross‐section of the

mortise chisel is proportioned to withstand heavy blows during mortising. Further, the

cross‐section is made stronger near the shank..

Comments are closed.