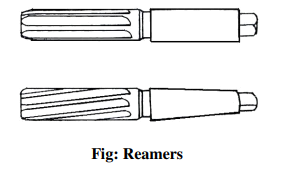

Reamers

Reaming is an operation of sizing and finishing a drilled hole, with the help of a cutting tool

called reamer having a number of cutting edges. For this, a hole is first drilled, the size of which

is slightly smaller than the finished size and then a hand reamer or machine reamer is used for

finishing the hole to the correct size.

Hand Reamer is made of High Carbon Steel and has left‐hand spiral flutes so that, it is prevented

from screwing into the whole during operation. The Shank end of the reamer is made straight so

that it can be held in a tap wrench. It is operated by hand, with a tap wrench fitted on the square

end of the reamer and with the work piece held in the vice. The body of the reamer is given a

slight tapper at its working end, for its easy entry into the whole during operation, it is rotated

only in clock wise direction and also while removing it from the whole.

Files

Filing is one of the methods of removing small amounts of material from the surface of a metal

part. A file is hardened steel too, having small parallel rows of cutting edges or teeth on its

surfaces.

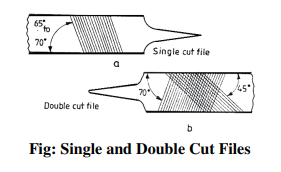

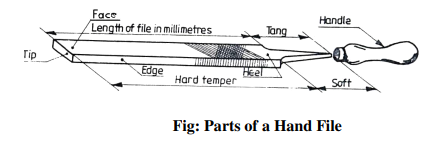

On the faces, the teeth are usually diagonal to the edge. One end of the file is shaped to fit into a

wooden handle. The figure shows various parts of a hand file. The hand file is parallel in width

and tapering slightly in thickness, towards the tip. It is provided with double cut teeth. On the

faces, single cut on one edge and no teeth on the other edge, which is known as a safe edge .

Files are classified according to their shape, cutting teeth and pitch or grade of the teeth. The figure shows the various types of files based on their shape.