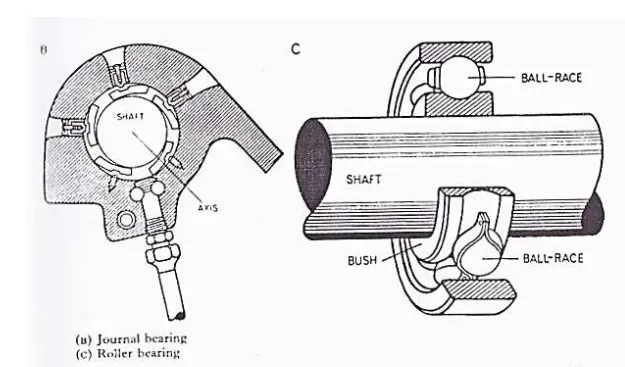

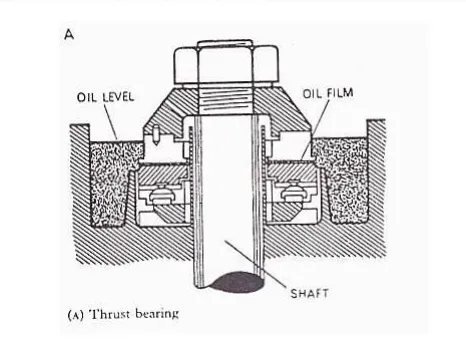

The machine tools in a workshop sometimes have their own electric motors, or they may take the power they need from a motor which feeds several machines. The shafts which carry the power from the motor to the machines need some kind of support to keep them steady. We call these supports bearings. There are different types of bearings for different purposes. We can classify them according to whether they take the load on the shaft or the thrust along the axis of the shaft. The former type is known as a journal bearing, and the latter type as a thrust bearing.

The rotating shaft bears on a stationary bush or tube. We therefore have two metal surfaces in close contact with each other, and sliding over each other often at high speed. This will cause friction and the bearing will become heated. So we have to protect the metal surfaces from overheating and damage. First of all, we avoid making the shaft and the bush of the same material. The shafting itself is generally of steel, but we use another metal such as cast-iron or bronze or white metal for the bush. At a certain temperature, the metal in the bush will seize or run, and this will prevent damage to the shaft. But of course it will not prevent overheating from occurring. However, we can reduce the danger of overheating by lubrication. We have a thin film of oil between the two metallic surfaces to keep them apart. The internal friction of oil is much less than the friction between two solids, and generates less heat. Lubrication also offers another advantage. A film of oil on the metal surfaces will prevent them from corroding by protecting them from the air. The sort of lubricant which we use depends largely on the running speed of the bearing. We can use grease in low-speed bearings, but grease offers more resistance to the turning movement of the shaft. A lighter oil causes less friction, and so an oily lubricant is better for high-speed bearings. The rotation of the shaft carries the film of oil round the inside of the bearing and keeps the shaft from contact with the bush which houses it. We can feed the oil into the bearing in several ways. Sometimes we allow it to drip down under the influence of gravity. More commonly, a pump or gun feeds it in under pressure. In motor-car and other engines, we half cover the bearing in an oil-bath, and oil splashes up into it. We can reduce the amount of friction even more with rolling bearings. The hardened steel balls in this type of bearing roll round in a finely-ground ball race, and make little more than point contact with the race.

Comments are closed.