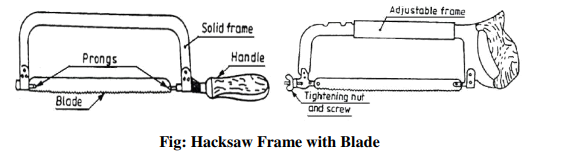

Hack Saw

The Hack Saw is used for cutting metal by hand. It consists of a frame, which holds a thin blade firmly in position. Hacksaw blade is specified by the number of teeth for centimeter. Hacksaw blades have a number of teeth ranging from 5 to 15 per centimeter (cm). Blades having lesser number of teeth per cm are used for cutting soft materials like aluminum, brass and bronze. Blades having larger number of teeth per centimeter are used for cutting hard materials like steel and cast Iron.

Hacksaw blades are classified as (i) All hard and (ii) flexible type. The all hard blades are made

of H.S.S, hardened and tempered throughout to retain their cutting edges longer. These are used

to cut hard metals. These blades are hard and brittle and can break easily by twisting and forcing

them into the work while sawing. Flexible blades are made of H.S.S or low alloy steel but only

the teeth are hardened and the rest of the blade is soft and flexible. These are suitable for use by

un‐skilled or semi‐skilled persons.

The teeth of the hacksaw blade are staggered, as shown in figure and known as a ‘set of teeth’.

These make slots wider than the blade thickness, preventing the blade from jamming.

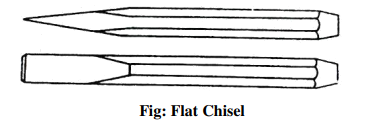

Chisels

Chisels are used for removing surplus metal or for cutting thin sheets. These tools are made from

0.9% to 1.0% carbon steel of octagonal or hexagonal section. Chisels are annealed, hardened and

tempered to produce a tough shank and hard cutting edge. Annealing relieves the internal

stresses in a metal. The cutting angle of the chisel for general purpose is about 60°.

Twist Drill

Twist drills are used for making holes. These are made of High speed steel. Both straight and taper shank twist drills are used. The parallel shank twist drill can be held in an ordinary self –centering drill check. The tapper shank twist drill fits into a corresponding tapered bore provided in the drilling machine spindle.

Taps and Tap Wrenches

A tap is a hardened and steel tool, used for cutting internal thread in a drill hole. Hand Taps are

usually supplied in sets of three in each diameter and thread size. Each set consists of a tapper

tap, intermediate tap and plug or bottoming tap. Taps are made of high carbon steel or high speed

steel.

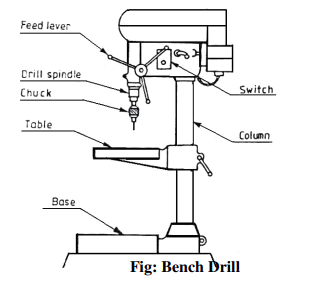

Bench Drilling Machine

Holes are drilled for fastening parts with rivets, bolts or for producing internal thread. Bench

drilling machine is the most versatile machine used in a fitting shop for the purpose. Twist drills,

made of tool steel or high speed steel are used with the drilling machine for drilling holes.

Following are the stages in drilling work

1. Select the correct size drills, put it into the check and lock it firmly

2. Adjust the speed of the machine to suit the work by changing the belt on the pulleys. Use

high speed for small drills and soft materials and low speed for large diameter drills and hard

materials.

3. Layout of the location of the pole and mark it with a center punch.

4. Hold the work firmly in the vice on the machine table and clamp it directly on to the machine

table.

5. Put on the power, locate the punch mark and apply slight pressure with the Feed Handle