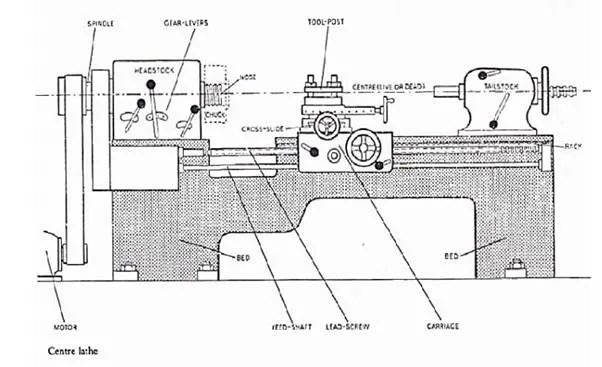

The lathe is one of the most useful and versatile machines in the workshop, and is capable of carrying out a wide variety of machining operations. The main components of the lathe are the headstock and tailstock at opposite ends of a bed, and a tool-post between them which holds the cutting tool. The tool-post stands on a cross-slide which enables it to move side wards across the saddle or carriage as well as along it, depending on the kind of job it is doing. The ordinary Centre lathe can accommodate only one tool at a time on the tool-post, but a turretlathe is capable of holding five or more tools on the revolving turret.

The lathe bed must be very solid to prevent the machine from bending or twisting under stress. The headstock incorporates the driving and gear mechanism, and a spindle which holds the workpiece and causes it to rotate at a speed which depends large lyon the diameter of the workpiece. A bar of large diameter should naturally rotate more slowly than a very thin bar the cutting speed of the tool is what matters. Tapered centres in the hollow nose of the spindle and of the tailstock hold the work firmly between them. A feed-shaft from the headstock drives the tool-post along the saddle, either forwards or backwards, at a fixed and uniform speed. This enables the operator to make accurate cuts and to give the work a good finish. Gears between the spindle and the feed-shaft control the speed of rotation of the shaft, and therefore the forward or backward movement of the tool-post. The gear which the operator will select depends on the type of metal which he is cutting and the amount of metal he has to cut off. For a deep or roughing cut the forward movement of the tool should be less than fora finishing cut.

Centres are not suitable for every job on the lathe. The operator can replace them by various types of chucks, which hold the work between jaws, or by a front-plate, depending on the shape of the work and the particular cutting operation. He will use a chuck, for example, to hold a short piece of work, or work for drilling, boring or screw-cutting. A transverse movement of the tool-post across the saddle enables the tool to cut across the face of the workpiece and give it a flat surface. For screw-cutting, the operator engages the lead-screw, a long screwed shaft which runs along in front of the bed and which rotates with the spindle. The lead-screw drives the tool-post forwards along the carriage at the correct speed, and this ensures that the threads on the screw are of exactly the right pitch. The operator can select different gear speeds, and this will alter the ratio of spindle and leadscrew speeds and therefore alter the pitch of the threads. A reversing lever on the headstock enables him to reverse the movement position.

Comments are closed.