There are a number of methods of joining metal articles together, depending on the type of metal and the strength of the joint which is required. Soldering gives a satisfactory joint for light articles of steel, copper or brass, but the strength of a soldered joint is rather less than a joint which is brazed, riveted or welded. These methods of joining metal arc normally adopted for strong permanent joints.

The simplest method of welding two pieces of metal together is known as pressure welding. The ends of metal are heated to a white heat – for iron, the welding temperature should be about 1300° C -in a flame. At this temperature the metal becomes plastic. The ends are then pressed or hammered together, and the joint is smoothed off. Care must be taken to ensure that the surfaces are thoroughly clean first, for dirt will weaken the weld. Moreover, the heating of iron or steel to a high temperature causes oxidation, and a film of oxide is formed on the heated surfaces. For this reason, a flux is applied to the heated metal. At welding heat, the flux melts, and the oxide particles are dissolved in it together with any other impurities which may be present. The metal surfaces are pressed together, and the flux is squeezed out from the centre of the weld. A number of different types of weld may be used, but for fairly thick bars of metal, a vee-shaped weld should normally be employed. It is rather stronger than the ordinary butt weld.

The heat for fusion welding is generated in several ways, depending on the sort of metal which is being welded and on its shape. An extremely hot flame can be produced from an oxyacetylene torch. For certain welds an electric arc is used. In this method, an electric current is passed across two electrodes, and the metal surfaces are placed between them. The electrodes are sometimes made of carbon, but more frequently they are metallic. The work itself constitutes one of them and the other is an insulated filler rod. An arc is struck between the two, and the heat which is generated melts the metal at the weld. A different method is usually employed for welding sheets or plates of metal together. This is known as spot welding. Two sheets or plates are placed together with a slight overlap, and a current is passed between the electrodes. At welding temperature, a strong pressure is applied to the metal sheets, The oxide film, and any impurities which are trapped between the sheets, are squeezed out, and the weld is made.

Steam Boilers

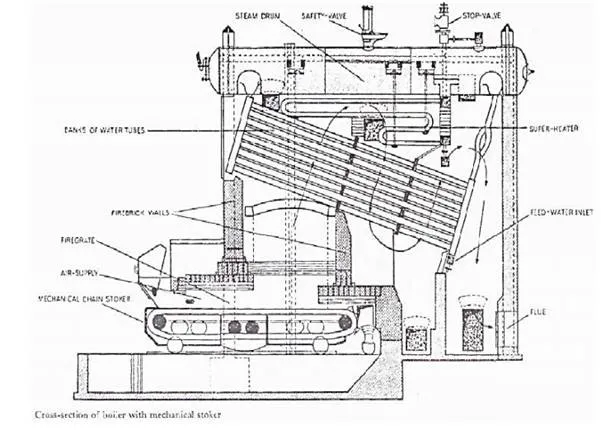

Large quantities of steam are used by modern industry in the generation of power. It is therefore necessary to design boilers which will produce high-pressure steam as efficiently as possible. Modern boilers are frequently very large, and are sometimes capable of generating 300,000 lb. Of steam per hour. To achieve this rate of steam production, the boilers should operate at very high temperatures. In some boilers, temperatures of over 1650° C may be attained. The fuels which arc burned in the furnace are selected for their high calorific value, and give the maximum amount of heat. They are often pulverised by crushers outside the furnace and forced in under pressure. Modern boilers which employ solid fuels arc usually too large to be hand-stoked, and stoking is then carried out by mechanical stokers, which ensure that an adequate quantity of fuel is conveyed into the furnace at the proper speed. The air which is needed by the fuel for combustion is blown across the fire grate by steam jets or fans. The amount of air which is allowed to enter is just more than sufficient for complete combustion of the fuel. An insufficient supply of air will prevent complete combustion, but any air in excess of the minimum merely reduces the temperature of combustion. The hot gases which are produced by the combustion of the fuel are circulated round banks of water-tubes. These are inclined at an angle over the furnace, and connect the upper and lower steam drums. A large proportion of the heat is absorbed by the water in the boiler. The remainder may be used to heat up the incoming air-supply through an air-heater. The water and steam in the boiler should circulate freely. The water and steam circuits are designed to allow the greatest possible fluid velocity to be attained, and rapid movement of the fluid is achieved by forced circulation. This assists rapid heating and also prevents the formation of steam pockets in the tubes.

Loss of efficiency in the boiler will be caused by the dissipation of heat through the walls of the combustion chamber. This heat loss can be considerably reduced by the use of fire bricks round the walls of the chamber. This helps to insulate the chamber and to conserve the heat which is generated. However, at the temperatures which are attainable in modern boilers, the solid walls of the furnace are liable to be damaged by excessive heat. To avoid this, they are often lined with water-tubes, and some of the heat of combustion is absorbed by the water.

Comments are closed.