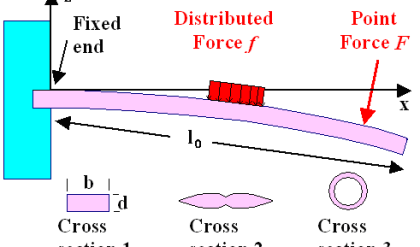

Materials testing has a long tradition and is based on the desire of scientists to measure the mechanical properties of materials and the need of design engineers to improve the performance and safety of buildings, bridges and machines. Mechanical sciences started with GALILEO GALILEI (1564-1642). He did not only promote COPERNICUS’ concept of a heliocentric planetary system, but studied the laws of falling bodies and strength of materials both theoretically and experimentally 2 . An actual engineering problem was the dependence of the strength or a bending bar on its cross sectional dimensions for which GALILEI designed an experiment shown in Fig. 2.1

The obvious question that arises from any experiment is:

· What can we learn from it? – or more precisely:

· How does this test configuration compare to the “real” situation?

For instance, can we take the fracture load obtained in the above test to design the supporting beams in a building? Finally, we reach the fundamental and still present-day problem of materials testing: are the test data measured on a specimen transferable to an actual largescale structure? Specimens used in materials testing are models in the sense of a “threedimensional representation, usually on a smaller scale, of a structure”, see above. In addition, they are of a simpler geometry and under simpler loading conditions. Whether the information from a (simplified) model may or may not be transferred to (complex) reality, is still controversial in many cases and cannot be answered by experiments alone. It needs a model in the sense of a theoretical description.

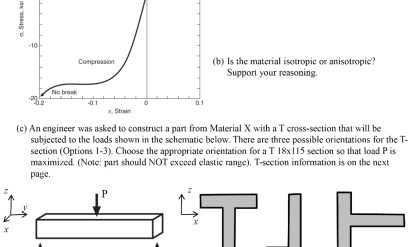

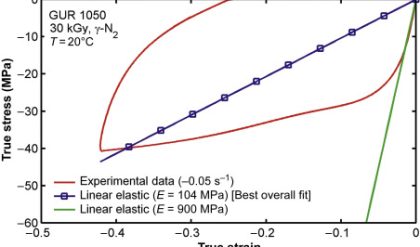

A deeper understanding of GALILEI’s bending problem would have required a theory, which did not exist in the 17th century. Nevertheless, engineers wanted to design structures and get information on the mechanical behaviour of different materials. Hence, they had to develop special test set-ups for various loading conditions such as tension, compression, bending, buckling, etc.. With expanding technology, other material properties became relevant, not only under static loading but also under impact or oscillating stresses. Engineers had found, that the ductility of a metallic material was an important property, which influences the safety margins of a structure or plant. In order to measure this ductility, the French metallurgist G. CHARPY designed his pendulum impact testing machine in 1901 to measure the mechanical work necessary to fracture a notched bar.

All these tests on comparatively simple specimens are performed in order to obtain information on the materials strength and toughness and to conclude to the mechanical behaviour and performance of complicated structural geometries und different kinds of loading and loading histories. The fundamental problem of materials testing, i.e. how much these tests tell us about inherent material properties, however, has still remained controversial. Separating material properties from structural properties is an intellectual process of abstracting, which is typical for modelling. It requires a theory, namely continuum mechanics, which has been developed in the late 19th and early 20th century and been permanently improved ever since.

Comments are closed.